Hydraulic silage baler | Hydraulic hay baler machine

The hydraulic silage baler can compact and bundle silage into manageable bales for easy storage, transportation, and feeding. With a capacity of 1–8 tons per hour, it meets the needs of both small farms and large commercial operations.

Silage—typically made from fermented grass or other green fodder crops—is a vital component of livestock feed preservation. By tightly baling the material, the machine prevents air exposure, reducing spoilage and ensuring long-term storage with minimal waste.

Available in various sizes and configurations, hydraulic silage balers are essential equipment for farmers aiming to improve silage management. They help maintain a consistent and nutritious feed supply for livestock throughout the year, supporting efficient farm operations and better animal health.

Hydraulic silage press baler for sale

The hydraulic silage baler is available in two configurations—dual-cylinder and triple-cylinder—to suit different farming needs.

- Dual-cylinder model: Can be powered by either a diesel engine or an electric motor for flexible operation.

- Triple-cylinder model: Solely electric-powered but offers higher operational efficiency than the dual-cylinder version.

- Bale size: Produces rectangular silage bales measuring 700 × 400 × 300 mm.

- Packaging: Each bale has an inner layer of PE and an outer layer of PP material for durability and preservation.

- Efficiency: The triple-cylinder variant delivers faster processing speeds, reducing labor needs.

By ensuring consistent bale dimensions and optimizing the packaging process, the hydraulic silage press baler helps farmers save time, improve feed preservation, and streamline overall silage management.

Dual-cylinder hydraulic hay baler

Our dual-cylinder hydraulic hay baler efficiently handles densely crushed materials with ease. With two oil cylinders, it ensures thorough pressing, resulting in tightly compacted bales. Powered by a 15kw motor or 28HP diesel engine, it delivers the necessary force for demanding tasks.

Compatible with optional equipment like automatic feeders, elevators, and 10-ton straw shredders, it seamlessly integrates into your workflow, enhancing productivity. Reliable and versatile, our baler is the ideal solution for efficient hay baling operations.

| Model | 9YK-70 |

| Power | 15kw motor or 28HP diesel engine |

| Displacement of oil cylinder | 63-80L/min |

| Normal-pressure of oil cylinder | 16Mpa |

| Bale size | 700*400*300mm |

| Bale Density | 300-400kg/h |

| Bundling efficiency | 1-2t/h |

| Weight | 1500kg |

| Dimension | 3400*2800*2700mm |

| Speed of Bundling Piston | 4-8m/min |

Triple-cylinder hydraulic straw press baler

Our triple-cylinder hydraulic straw press baler offers enhanced efficiency by compressing straw more times during operation compared to dual-cylinder balers. Powered by a 22kW electric motor, it effortlessly handles various tasks. Additionally, it can be paired with a 15-ton straw kneader and a 10-ton elevator, further boosting productivity.

With multiple compressions, this machine ensures thorough compaction of straw, resulting in tighter bales. This design aims to improve efficiency and reduce operational time, providing greater convenience for your farm operations.

| Item | 9YK-130 |

| Power | 22kw |

| Displacement of Oil Cylinder | 80L/min |

| Normal Pressure of Oil Cylinder | 18Mpa |

| Bale Size | 700*400*300mm |

| Bundling Efficiency | 6-8t/h |

| Bale Density | 800-1100kg/m3 |

| Weight | 2600kg/h |

| Dimension | 4300*2800*2000mm |

| Speed of Bundling Piston | 4-8m/min |

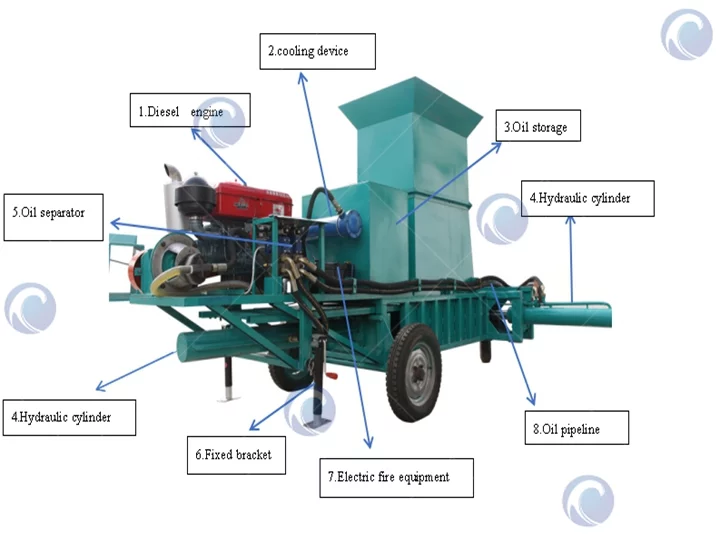

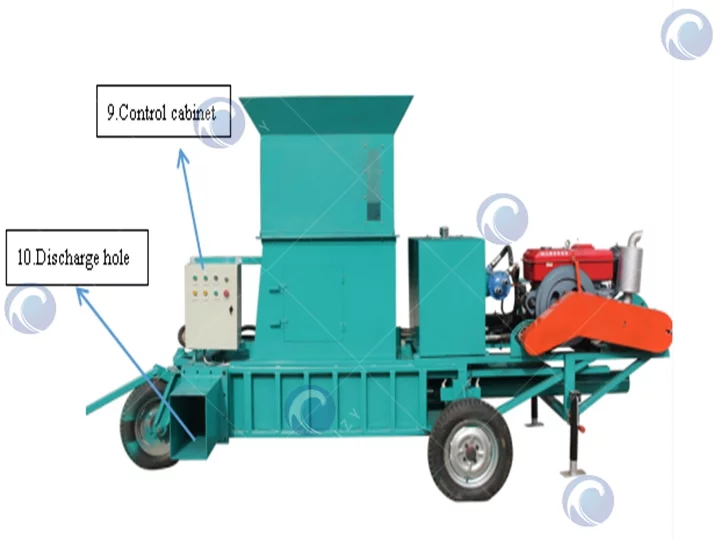

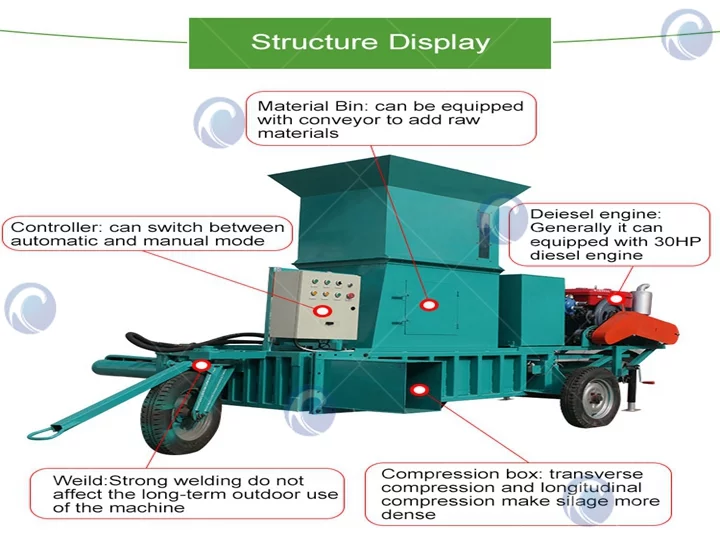

Structure of the hydraulic silage baler

How does the hydraulic silage baler work?

Feeding raw materials

Silage materials such as grass, corn stalks, or wheat straw are fed into the inlet of the Hydraulic silage baler, either manually or via a conveyor belt.

Cutting or shredding

The raw materials pass through a hay cutter or straw kneading machine, which chops them into shorter lengths suitable for baling, ensuring better compression and uniform packaging.

Compression and forming

The hydraulic system drives the compression plate to apply high pressure, forming the material into regular bale shapes.

Bale wrapping

The formed silage bales are wrapped with plastic film (PE inner layer + PP outer layer) or special woven bags to keep out air, prevent mold, and extend preservation time.

Automatic control and bale discharge

The entire process is managed by a PLC automatic control system or electric control cabinet, allowing one-key operation. Finished bales are discharged automatically after packing.

Finished bale storage

The Hydraulic silage baler produces bales with uniform dimensions, making them easy to stack, store, transport, and feed later.

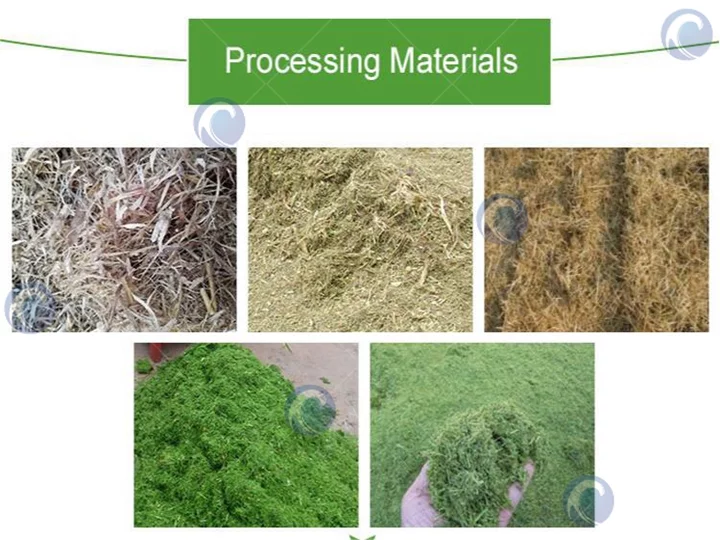

What materials are suitable for the hydraulic baler machine?

The hydraulic baler machine is designed to handle a wide range of materials, making it a versatile tool for various agricultural and industrial applications.

Suitable materials include straw, silage corn straw, wheat straw, imperial bamboo grass, wood shavings, sawdust, pepper, and more.

These materials can be effectively compressed and baled by the hydraulic baler, facilitating storage, transportation, and processing. Whether you’re dealing with agricultural residues, biomass, or other bulk materials, the hydraulic baler machine offers an efficient solution for packaging and handling. Its versatility makes it an indispensable asset for farms, recycling facilities, and manufacturing plants alike.

Key advantages of hydraulic hay baler machine

- Streamlined design, intuitive operation, and reliable performance.

- Fully automated baling process, reducing the need for manual labor and cutting down on operational costs.

- Compression of grass into denser bales, facilitating convenient handling, transportation, and storage.

- Versatile power options are available: diesel engine or electric motor for flexibility in various operating environments.

- Prolonged shelf life, with natural preservation capabilities extending up to 3 years.

- Cost-effective storage solutions using PE & PP bags, minimizing packaging expenses.

- Improved efficiency and superior bale consistency.

Conclusion

With outstanding performance and ease of operation and maintenance, our products are designed to meet your needs. Whether it’s compressing silage or baling hay, we are committed to providing the best solutions to help you increase productivity and reduce costs.

Additionally, we recommend our silage baler and hay baling machine, both of which offer excellent performance and reliability to meet various needs in agricultural production. Contact us now to learn more and let us work together to create success in agricultural production!