Grass chaff cutter machine | Animal grass straw feed crusher

The Grass Chaff Cutter Machine is a high-efficiency fodder processing solution for cutting straw, grass, corn stalks, and other forage materials into uniform lengths of 1–5 cm.

With a production capacity ranging from 1 ton to 10 tons per hour, this machine meets the needs of both small-scale farms and large livestock operations. It supports multiple power configurations, including 3kW–15kW electric motors, diesel engines, and gasoline engines, ensuring flexible use in various field conditions.

Animal grass straw feed crusher not only improves feed palatability and animal digestion but also significantly reduces labor intensity, making it an indispensable tool for modern animal husbandry.

Hot-selling grass chaff cutter machine

Our hot-selling grass chaff cutter machine offers versatility and efficiency tailored to meet diverse farming needs. With multiple models available, customers can select the ideal machine based on their specific requirements and desired output.

What sets our grass chaff cutter apart is its flexibility in power options, including electric motors, diesel engines, or gasoline engines, ensuring suitability for various operating environments.

Each model of our fodder cutter machine features a convenient conveyor belt system, automating the feeding process into the cutting chamber. This not only enhances machine efficiency but also reduces labor requirements, optimizing overall productivity.

Supplementary equipment of animal grass straw feed crusher

Our supplementary equipment for the animal grass straw feed crusher extends beyond just cutting and grinding machines. At Taizy, we offer a comprehensive range of agricultural machinery to meet all your farming needs.

In addition to our grass cutting and shredding machines, we provide straw picking and baling machines, among others. This ensures that you have everything required for efficient fodder processing on your farm.

Once the material has been cut and crushed into small pieces using our feed crusher, you can further optimize your operations with our silage wrapping machine.

This equipment bundles the silage feed, extending its storage time and preserving its nutritional value for longer periods.

Applications of the fodder cutter

The fodder cutter machine is versatile, handling various materials such as cotton, corn, sorghum stalks, and more. It finds wide applications in feeding pigs, cattle, sheep, and poultry, improving feed palatability and utilization rates.

Developed for large-scale shredding tasks, it efficiently processes crop straws, enhancing forage quality for livestock. In summary, this machine is essential for producing high-quality feed, meeting the nutritional needs of various livestock and poultry species.

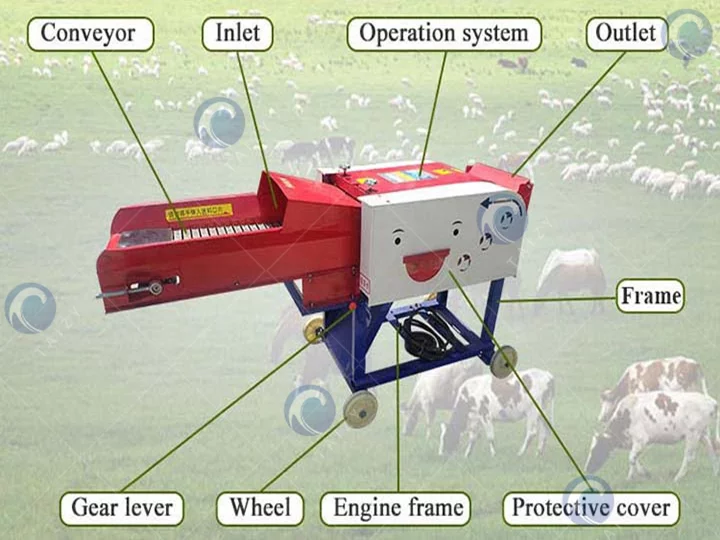

Structure of the hay chaff cutter machine

How does the straw cutting machine work?

- The straw cutting machine begins operation by transporting raw materials to the kneading chamber using a conveyor belt.

- Inside the kneading chamber, the materials are cut and kneaded through the high-speed interaction between rotating hammer blades and kneading plates.

- The machine features adjustable hammer blades that allow users to control the kneading intensity and the degree of straw crushing.

- As the straw is automatically fed through the conveyor, it is flattened, sliced, squeezed, and kneaded to break down the tough nodes on the stalk surface.

- After processing, the straw is transformed into finely shredded forage that is easier for livestock to digest and absorb without compromising its nutritional value.

Parameters of grass chaff cutter machine

| Model | 9ZR-2.5T | 9ZR-3.8A | 9ZR-3.8B | 9ZR-4.8T | 9ZR-6.8 | 9ZR-8 |

| Power | 3-4.5 kw | 3-4.5 kw | 3-4.5 kw | 5.5 kw | 7.5 kw | 11 kw |

| Capacity | 2500kg/h | 3800kg/h | 3800kg/h | 4800kg/h | 6800kg/h | 8000kg/h |

| Size | 1350*490*750mm | 1650*550*900mm | 1750*550*900mm | 1750*600*930mm | 2283*740*1040mm | 3400*830*1200mm |

| Weight | 67 kg | 88 kg | 93 kg | 116 kg | 189 kg | 320 kg |

Key advantages of the grass chaff cutter machine

- Versatility. The Grass Chaff Cutter Machine is capable of processing a wide range of materials, including grass, straw, corn stalks, and more, making it suitable for various agricultural applications.

- Efficiency. This machine efficiently cuts and shreds materials, saving time and labor compared to manual processing methods. Its automated operation streamlines the fodder processing workflow.

- Customization. With adjustable settings for cutting length and output, the Grass Chaff Cutter Machine can be tailored to meet specific feeding requirements and production goals.

- Enhanced feed quality. By finely chopping and shredding materials, the machine improves the digestibility and palatability of fodder, leading to better feed utilization and animal health.

- Durability. Built with high-quality materials and robust construction, the Grass Chaff Cutter Machine is designed for long-term use in demanding agricultural environments, ensuring reliable performance and longevity.

- Cost-effectiveness. Investing in a Grass Chaff Cutter Machine can lead to cost savings over time by reducing manual labor costs and increasing operational efficiency in fodder processing.

- Environmental benefits. By efficiently processing agricultural residues into fodder, the machine helps minimize waste and promotes sustainable farming practices.

Invest in our chaff cutter

In conclusion, as a leading manufacturer of chaff cutters, we are committed to providing efficient and reliable solutions to meet your fodder processing needs. Our products are not only versatile, efficient, and durable but also customizable to meet your specific requirements.

If you’re interested in our chaff cutter or have any inquiries, feel free to contact us. Our dedicated team is here to provide support and assistance. Get in touch with us now to learn more and request a quote!