Straw baler machine | Hay pickup baling machine

The Straw baler machine is used to collect, compress, and tie dried straw, hay, or crop stalks into compact bales for easy storage and transport. It mainly includes two types: the Round Hay Baler and the Square Straw Picking Machine.

With a working capacity of 1.3–1.65 acres per hour, the Straw baler machine improves efficiency, reduces labor, and adds value by turning loose straw into manageable, high-density bales.

Hay pickup baling machine for sale

As a professional agricultural company, we offer top-quality hay pickup baling machines tailored to meet diverse farming needs. Our lineup includes round and square balers, each powered by a three-point suspension PTO with the tractor. The round baler efficiently handles round bales using twine or net, while the square baler produces secure square bales using ropes.

Additionally, we offer hay cutters with crushing capability and baler machines for added functionality. Choose our hay pickup baling machines for efficient, reliable, and versatile hay baling operations.

Type 1: Round hay baler

The Round Hay Baler is capable of using either net rope or hemp rope for bundling. It forms round bales measuring 70×100 mm, ensuring uniform size and density. The machine is equipped with essential components such as a hydraulic cylinder, switch compartment lever, fender, and PTO system, all of which work together to ensure stable and efficient baling performance.

| Model | ST80*100 |

| Weight | 680kg |

| Power of tractor | More than 40hp |

| Overall Dimension | 1.63*1.37*1.43m |

| Baler Size | Φ800*1000mm |

| Baler weight | 40-50kg |

| Capacity | 1.3-1.65acre/h |

Type 2: Square Straw Picking Machine

The square hay picking and baling machine is an ideal choice for efficiently harvesting and baling corn, rice, wheat, cotton, and other straw and forage crops. This machine offers automated stubble kneading and baling capabilities, streamlining the entire process.

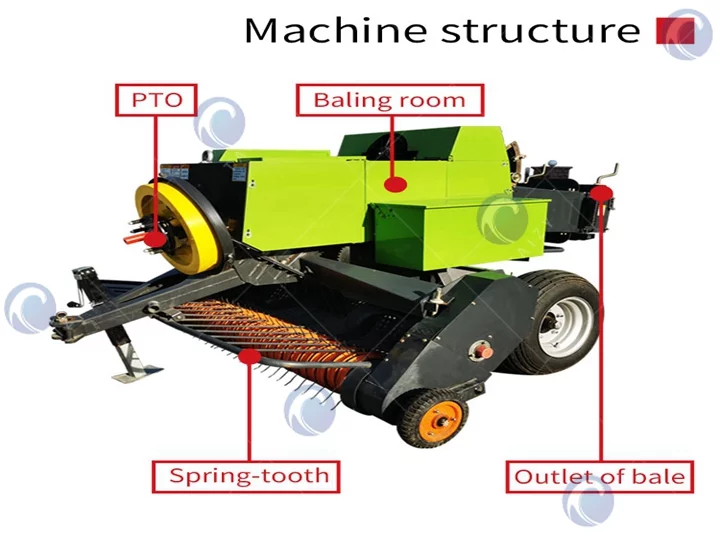

Its structure includes key components such as the power take-off (PTO), popping teeth, baling chamber, and bale outlet, ensuring efficient and reliable performance. Popular in the Middle East, this machine is the preferred choice for farmers looking to maximize productivity and profitability in straw baling operations.

Straw baler machine structure

| Model | 9YFQ-2.2 |

| Bale length | 300-1300mm |

| Bale density | 110-180kg/m³ |

| Pickup width | 2200mm |

| Bale cross-sectional area | 360*460mm |

Why need to buy a hay pickup baling machine?

- Better Hay Quality: Tightly compresses materials to lower moisture and preserve nutrients, ensuring high-quality livestock feed.

- Reduced Crop Loss: Quick baling minimizes weather exposure and handling damage, increasing overall yield.

- Versatile Use: Adapts to different terrains and crop types for flexible field operations.

- Resource Conservation: Maximizes the use of crop residues for feed, bedding, or biomass, reducing waste and promoting sustainability.

Suitable materials for straw baler machine

Straw baler machines can bale a wide range of materials, including wheat, rice, barley, and oat straw; dry grasses like alfalfa and clover; corn stalks; sugarcane bagasse; miscanthus (elephant grass); and hemp stalks.

These materials are ideal for compacting, storing, and transporting efficiently.

How does the straw baler machine work?

- Material Collection: The tractor-powered machine picks up straw or grass from the ground and delivers it to the conveying platform.

- Feeding & Compression: The screw conveyor pushes materials into the baling chamber, where the piston compresses them tightly.

- Baling & Strapping: Once the bale reaches the set length, the knotter automatically ties it with two ropes.

- Bale Discharge: The finished bale is pushed out through the outlet and dropped to the ground for easy collection.

Contact us

We prioritize both product quality and performance, aiming to deliver the best user experience to our customers. Whether in the manufacturing process or during product usage, we maintain a professional approach, ensuring that each machine meets the highest standards.

Furthermore, we offer a one-year after-sales service to ensure customer satisfaction and confidence throughout the usage period. Customers can rely on us for timely assistance and support by providing feedback on any issues they encounter. Whether it’s inquiries, after-sales service, or technical support, we are dedicated to serving our customers and ensuring their satisfaction and success.

Feel free to contact us for inquiries. We look forward to collaborating with you to provide high-quality products and services.