TMR feed mixing machine | Fodder mixer

The TMR (Total Mixed Ration) feed mixing machine can create a nutritionally balanced diet by thoroughly blending silage, hay, grains, protein supplements, and minerals. This ensures that every feeding provides consistent nutrition, improving feed efficiency while saving time, reducing labor, and minimizing feed waste.

To accommodate different farming needs, we offer two models: the vertical feed mixing machine, suitable for fibrous materials and compact spaces, and the horizontal fodder mixer, ideal for large-scale operations requiring faster and more uniform mixing. Both models are available in capacities ranging from 5 to 12m³, providing flexible and efficient solutions for modern livestock farming.

Vertical feed mixing machine

- Our vertical feed mixer is a space-saving solution suitable for farms with limited space.

- It features a vertical mixing chamber design, allowing for efficient mixing of various feed ingredients.

- Despite its compact design, it offers high mixing efficiency and can handle a wide range of feed materials.

- With competitive pricing, the vertical feed mixing machine provides an affordable yet reliable solution for commercial feed mixing needs.

Type 2: Horizontal fodder mixer

- It features a horizontal mixing chamber, offering a higher mixing capacity compared to the vertical model.

- The horizontal design ensures thorough mixing of feed ingredients, resulting in a uniform and well-balanced ratio.

- While not portable, it can be easily moved using a tractor, providing convenience.

- Additionally, the horizontal feed mixing machine is equipped with a spreading function, enhancing operational flexibility and versatility.

Fodder mixing machine advantages

Advanced and Rational Design

- The bottom of the mixing chamber is made of high-quality alloy steel, suitable for operation in harsh environments.

- The unique cutting blades are made of highly wear-resistant materials, and the auger blades are made of high-quality alloy steel, greatly improving the product’s service life.

Flexible, Convenient, and Safe Operation

- Can directly mix silage, various types of straw, and other fibrous feeds into the mixing chamber.

- Each batch of feed cutting and mixing takes approximately 10-25 minutes, ensuring efficient operation.

Highly Efficient and Energy Saving

- Depending on the volume of the chamber, each fodder mixing machine can feed 200-2000 cows or 500-5000 sheep per day.

- It can replace the work of more than 20 workers, reducing labor intensity and improving feeding efficiency.

These features make the fodder mixing machine efficient, durable, and easy to operate. It provides convenience and benefits to farmers while also improving the quality and efficiency of feed mixing.

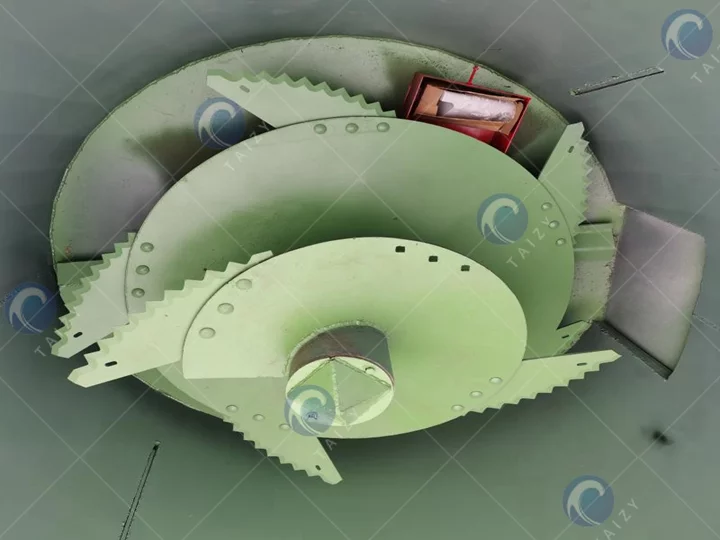

Silage blending machine structure

The Silage blending machine consists of several main components, including an electric motor, gearbox, frame, mixing chamber, auger, and discharge outlet.

How does the feed mixer machine work?

- The electric motor provides power, which is transmitted to the main auger of the mixing chamber through the gearbox.

- The main auger drives the secondary auger in the middle of the mixing chamber for coordinated movement.

- The main auger features a spiral blade rack equipped with helical and crescent-shaped blades.

- As the auger rotates, the blades perform cutting, flipping, squeezing, kneading, convection, and diffusion actions.

- This multi-directional mechanical action circulates and mixes the feed materials thoroughly within the chamber.

- The machine reduces coarse feed into finer particles, blends dry and wet materials, and mixes leafy and granular feed evenly, producing high-quality feed.

Parameters of feed mixing machine

| Model | TMR-5 | TMR-9 | TMR-12 |

| Capacity (m³) | 5 | 9 | 12 |

| Auger speed (R/min) | 23.5 | 23.5 | 23.5 |

| Weight (kg) | 1600 | 3300 | 4500 |

| Dimension (mm) | 3930*1850*2260 | 4820*2130*2480 | 5600*2400*2500 |

| Structural shape | Fixed | Fixed | Mobile |

| Matched power (kW) | 11-15 | 22-30 | 50-75 |

| Blade quantity (pcs) | Fixed blades: 7 Mobile blades: 34 | Fixed blades: 9 Mobile blades: 56 | totally 192 |

What is the price of the TMR feed mixing machine?

The price of our TMR feed mixing machines varies depending on several factors, including capacity, features, and additional services. With different models and production capacities available, prices can vary significantly.

To get an accurate price quote tailored to your specific needs, including capacity requirements and desired features, please contact us directly. Our knowledgeable sales team will be happy to provide you with a competitive quote and answer any questions you may have.

Contact us today to discuss your requirements and discover the perfect TMR feed mixing solution for your operation!

Invest in our forage mixer

Our TMR forage mixer can be used independently or in combination with our chaff cutter machine, providing you with a comprehensive feed processing solution. Whether you need mixing, chopping, or processing of forage, we have the efficient and reliable equipment you need.

Feel free to contact us to learn more and to tailor the perfect feed processing solution for your needs!